|

|

|

|

#1426 |

|

..........

Join Date: Dec 2006

Casino cash: $4167901

|

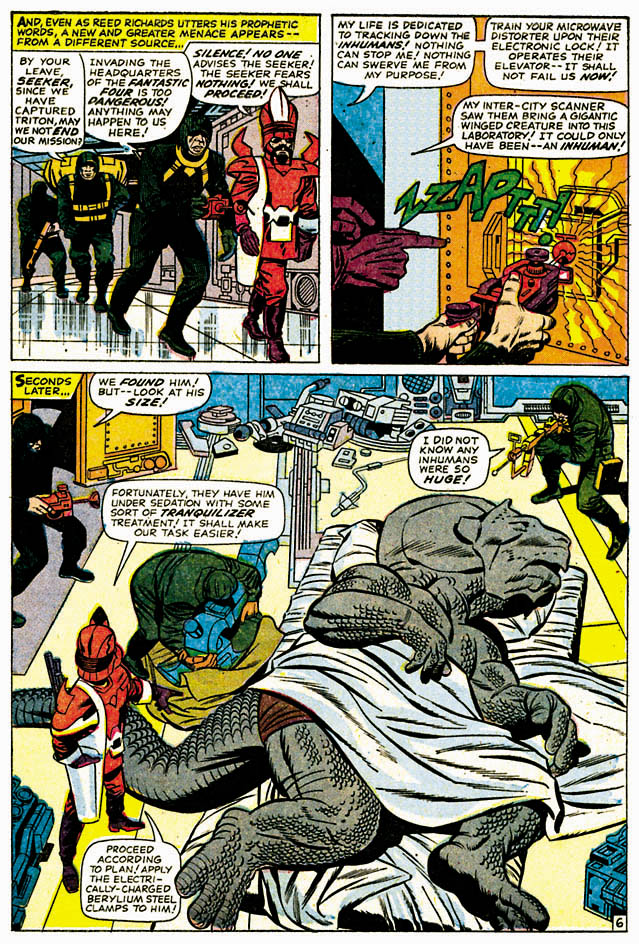

can you find the "Beryllium Reference" in this comic? |

|

Posts: 28,392

|

|

|

|

#1427 |

|

..........

Join Date: Dec 2006

Casino cash: $4167901

|

Beryllium Chloride can affect you when breathed in

|

|

Posts: 28,392

|

|

|

|

#1428 |

|

..........

Join Date: Dec 2006

Casino cash: $4167901

|

There is a great parallel between metals and our civilized history. The use of a particular metal in day-to-day activities reflected the course of technology during a period of history and, quite often, influenced the rate at which a particular civilization advanced. Indeed, the metal copper has had a long, varied and extremely interesting history. Accordingly, it has served as the signpost of technological development over the centuries.Copper was the first metal that man used for tools and implements. It is conceivable that the primary reason for the early development of practical applications for this versatile metal was that copper, like gold and silver, is sometimes found in a pure state. As such, it can be beaten into shape even when cold. The earliest use of copper was by the Sumerians and Egyptians some 7,000 years ago. Long before Europeans reached the continent of North America, American Indians were using copper for beads and tools. Today, copper and copper alloys are used extensively in the manufacture of a multitude of applications - electric power, water supply, air cooling, telecommunications, computers, consumer products and countless electronic devices. Copper is the most widely used of all metals for today's diverse technologies. Copper is not only widely used but also simple to use. It is easily worked and ductile. It has pleasing color and luster, and forms alloys readily with many metals, increasing its versatility. There are more than 100 copper alloys, including zinc-brasses, tin- bronzes, nickel silvers and cupro nickels. Choice among the alloys in the copper-based system is one with slightly less than 2 percent beryllium (Be). The beryllium allows this alloy to be processed into strength levels higher than all other copper alloys. Beryllium is an alkaline earth metal. As an ore, beryl, or aluminum beryllium silicate, is a hexagonal crystal and contains as much as 15 percent beryllium. It is mined sometimes with aquamarine (a blue beryl) and emerald. In its metal form, it is the lightest of all the rigid metals and among the strongest. It has very high resistance to heat and corrosion, a very precise elastic limit, low mass atomic absorption, high infrared reflectivity and conductivity equal to that of aluminum. Accordingly, alloys of beryllium and copper have become technology's material of choice in the manufacture of electrical and thermal conducting springs because of their strength, heat dissipation and resistance to fatigue. Beryllium-copper alloys have desirable properties facilitating their use in a variety of demanding applications. However, it is not commonly realized that there are two distinct families of properties. The first is high strength, and the second is high conductivity. The high-strength alloys (C17200 and C17000) are less dense (.298 lbs./cu. in.) than conventional specialty coppers. This often results in a yield of up to 7 percent more feet per pound than high-strength phosphor bronze. The high-conductivity beryllium-copper alloys (C17500 C17510 and C17410) are ideally suited to applications requiring high operating temperatures, or high strength and conductivity. The following are specific beryllium-copper alloy advantages: High strength-to-weight ratio High electrical and thermal conductivity Long service life Wide range of mechanical properties Wide range of tempers High resistance to stress relaxation High fatigue strength Good corrosion resistance Resistance to anelastic behavior

|

|

Posts: 28,392

|

|

|

|

#1429 |

|

..........

Join Date: Dec 2006

Casino cash: $4167901

|

Beryllium copper is available in strip, wire, rod, bar, plate tubing, billet, casting ingot and extruded shapes. Beryllium-copper wire is one of the more widely used product forms of this feature-rich alloy. Wire can be drawn to fine sizes, or rolled in rect-angles, squares, profiled shapes or fine ribbon. This, in conjunction with the diverse attributes of the alloy, creates wire applications which include, but are not limited to, long-travel coil springs; spring-loaded test probes; connectors; bandoleer connector compliant pins; axial-gripping electronic contacts; speaker leads; and miniature coined and cold-forged electronic contacts. In general, beryllium copper displays many of the desirable plating and joining characteristics which are well documented for copper alloys. However, because of the ability that this alloy has to be heat treated and the high affinity that beryllium has in forming oxides at elevated temperatures, surface cleanliness is a critical factor if articles are to be subsequently plated or joined by soldering, brazing or welding. Surface oxides, oil and the like must be thoroughly removed - preferably before and after the heat treatment process. Many applications permit using pretempered and/or pre-plated wire. Cautious selection of the plating and condition of the starting wire can eliminate unnecessary processing steps. Heat treating and/or stress relieving finished parts is very common in highly stressed coil springs. Many applications may permit the use of a fine coating of plating on wire to aid in coiling of pretempered (already heat treated) wire. Silver and gold possess a low coefficient of friction, which allows the reduction of surface forming stresses. Sometimes the reductions are significant enough that costly stress relieving may be omitted. Although there are great advantages in processing formed and heat treated parts, processing parts from both heat treated and pretempered wire are common practices. Where a cyclic stress environment exists, such as with electronic and electric-contact springs, beryllium-copper wire has an extremely successful performance record. The alloy performs quite well in this area and also under conditions of high-impact stress. Accordingly, heavier sections of the alloy can be found in applications such as aircraft landing-gear bushings, where high fatigue strength and resistance to galling is of paramount performance. These applications are not dissimilar to that of computer printers where fine, gold-plated coil springs (.004-.0058 in. diameter) are used, in conjunction with a brass contact plunger, to produce spring-loaded contacts that interface with ink-release contacts in the ink-jet printer cartridge signaling ink release patterns.Beryllium-copper alloys offer the design engineer a broad range of alluring attributes: high electric and thermal conductivity, wide operating temperature ranges, heat treatability and excellent resistance to fatigue. The fact that this alloy is nonsparking is a definite asset in spring design, where sparks are a major concern. Beryllium copper is nonmagnetic and is magnetically unaltered by heat treatment or cold work. It is also quite effective as an electromagnetic insulator/radio frequency insulator. The alloy is resistant to galling and provides inherent good wear resistance. It is selected as a material to be used in applications where abrasive contact with other surfaces occurs. These applications can include use as test-probe tube plungers or as even larger, die casting plungers for aluminum die cast machines. Beryllium copper is presently well known for the high reliability and long life it provides to springs for automotive electronics, windshield wiper switches, cruise control switches, power door locks, and power seat, dash and light switches. It is now finding its way to the other side of the fire wall with its use in springs and contacts from the high-temperature high-conductivity side of the beryllium-copper family. The alloys C17410 and C17510 have been established as premier high-temperature copper-based materials. Sometimes known as RWMA Class III, beryllium-copper welding electrodes are used where high conductivity, good strength and resistance to welder tip mushrooming are important. It is also widely used as die-casting plunger tips, where resistance to shot sleeve wear and erosion from contact with the molten aluminum together make a very hostile environment. This alloy family has numerous spring and spring-contact applications in high-voltage circuit breakers and fuse switches - small and large. In some of these applications, the base metal is stress-loaded for years under extreme environmental conditions.

|

|

Posts: 28,392

|

|

|

|

#1430 |

|

..........

Join Date: Dec 2006

Casino cash: $4167901

|

History(Gr. beryllos, beryl; also called Glucinium or Glucinum, Gr. glykys, sweet) Discovered as the oxide by Vauquelin in beryl and in emeralds in 1798. The metal was isolated in 1828 by Wohler and by Bussy independently by the action of potassium on beryllium chloride. SourcesBeryllium is found in some 30 mineral species, the most important of which are bertrandite, beryl, chrysoberyl, and phenacite. Aquamarine and emerald are precious forms of beryl. Beryl and bertrandite are the most important commercial sources of the element and its compounds. Most of the metal is now prepared by reducing beryllium fluoride with magnesium metal. Beryllium metal did not become readily available to industry until 1957. PropertiesThe metal, steel gray in color, has many desirable properties. As one of the lightest of all metals, it has one of the highest melting points of the light metals. Its modulus of elasticity is about one third greater than that of steel. It resists attack by concentrated nitric acid, has excellent thermal conductivity, and is nonmagnetic. It has a high permeability to X-rays and when bombarded by alpha particles, as from radium or polonium, neutrons are produced in the amount of about 30 neutrons/million alpha particles. At ordinary temperatures, beryllium resists oxidation in air, although its ability to scratch glass is probably due to the formation of a thin layer of the oxide. UsesBeryllium is used as an alloying agent in producing beryllium copper, which is extensively used for springs, electrical contacts, spot-welding electrodes, and non-sparking tools. It is applied as a structural material for high-speed aircraft, missiles, spacecraft, and communication satellites. Other uses include windshield frame, brake discs, support beams, and other structural components of the space shuttle. Because beryllium is relatively transparent to X-rays, ultra-thin Be-foil is finding use in X-ray lithography for reproduction of microminiature integrated circuits. Beryllium is used in nuclear reactors as a reflector or moderator for it has a low thermal neutron absorption cross section. It is used in gyroscopes, computer parts, and instruments where lightness, stiffness, and dimensional stability are required. The oxide has a very high melting point and is also used in nuclear work and ceramic applications. HandlingBeryllium and its salts are toxic and should be handled with the greatest of care. Beryllium and its compounds should not be tasted to verify the sweetish nature of beryllium (as did early experimenters). The metal, its alloys, and its salts can be handled if certain work codes are observed, but no attempt should be made to work with beryllium before becoming familiar with proper safeguards

|

|

Posts: 28,392

|

|

|

|

#1431 |

|

Take a Chill Pill

Join Date: Nov 2006

Location: South Carolina

Casino cash: $6190295

|

This is the periodic table symbol for Beryllium. |

|

Posts: 44,604

|

|

|

|

| KurtCobain |

|

This message has been deleted by KurtCobain.

Reason: don't do drugs!

|

|

|

#1432 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

beryllium is available in several forms including foil, lump, and powder. Small and large samples of beryllium foil can be purchased from Advent Research Materials via their web catalogue.

|

|

Posts: 22,269

|

|

|

|

#1433 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

Beryllium is a Group 2 (IIA) element. At ordinary temperatures, beryllium resists oxidation in air. Its ability to scratch glass is probably due to the formation of a thin layer of the oxide. Aquamarine and emerald are precious forms of the mineral beryl, [Be3Al2(SiO3)6].

|

|

Posts: 22,269

|

|

|

|

#1434 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

Here is a brief summary of the isolation of beryllium.

Beryllium metal is available commercially and so would never normally be made in the laboratory. Its extraction from ores is complex. The mineral beryl, [Be3Al2(SiO3)6] is the most important source of beryllium. It is roasted with sodimu hexafluorosilicate, Na2SiF6, at 700°C to form beryllium fluoride. This is water soluble and the beryllium may be precipitated as the hydroxide Be(OH)2 by adjustment of the pH to 12. |

|

Posts: 22,269

|

|

|

|

#1435 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

Pure beryllium may be obtained by electrolysis of molten BeCl2 containing some NaCl. The salt is added since the molten BeCl2 conducts very poorly. Another method involves the reduction of beryllium fluoride with magnesium at 1300°C.

BeF2 + Mg → MgF2 + Be |

|

Posts: 22,269

|

|

|

|

#1436 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

People working or living near beryllium industries have the greatest potential for exposure to beryllium. Lung damage has been observed in people exposed to high levels of beryllium in the air. About 1-15% of all people occupationally-exposed to beryllium in air become sensitive to beryllium and may develop chronic beryllium disease (CBD), an irreversible and sometimes fatal scarring of the lungs. CBD may be completely asymptomatic or begin with coughing, chest pain, shortness of breath, weakness, and/or fatigue.

|

|

Posts: 22,269

|

|

|

|

#1437 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

Beryllium has been found in at least 535 of the 1,613 National Priorities List sites identified by the Environmental Protection Agency (EPA).

|

|

Posts: 22,269

|

|

|

|

#1438 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

What is beryllium?

Beryllium is a hard, grayish metal naturally found in mineral rocks, coal, soil, and volcanic dust. Beryllium compounds are commercially mined, and the beryllium is purified for use in nuclear weapons and reactors, aircraft and space vehicle structures, instruments, x-ray machines, and mirrors. Beryllium ores are used to make speciality ceramics for electrical and high-technology applications. Beryllium alloys are used in automobiles, computers, sports equipment (golf clubs and bicycle frames), and dental bridges. |

|

Posts: 22,269

|

|

|

|

#1439 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

What happens to beryllium when it enters the environment?

* Beryllium dust enters the air from burning coal and oil. This beryllium dust will eventually settle over the land and water. * It enters water from erosion of rocks and soil, and from industrial waste. Some beryllium compounds will dissolve in water, but most stick to particles and settle to the bottom. * Most beryllium in soil does not dissolve in water and remains bound to soil. * Beryllium does not accumulate in the food chain. |

|

Posts: 22,269

|

|

|

|

#1440 |

|

Reset

Join Date: Aug 2006

Location: Parts Unknown

Casino cash: $6966765

|

How might I be exposed to beryllium?

* The general population is exposed to normally low levels of beryllium in air, food, and water. * People working in industries where beryllium is mined, processed, machined, or converted into metal, alloys, and other chemicals may be exposed to high levels of beryllium. People living near these industries may also be exposed to higher than normal levels of beryllium in air. * People living near uncontrolled hazardous waste sites may be exposed to higher than normal levels of beryllium. |

|

Posts: 22,269

|

|

|

| Thread Tools | |

| Display Modes | |

|

|